Unlocking the Future with 3D Printing: A Revolution in Manufacturing

In the past few decades, technology has taken monumental leaps, transforming industries and the way we live. Among the most groundbreaking innovations is 3D printing, also known as additive manufacturing. This transformative technology has the potential to revolutionize how we design, create, and produce objects. From prototyping to full-scale production, 3D printing is no longer just a novelty—it’s a driving force in the modern world.

What is 3D Printing?

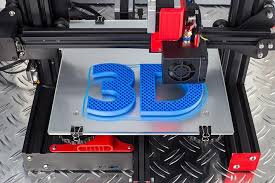

At its core, 3D printing is the process of creating three-dimensional objects from a digital design. Unlike traditional subtractive manufacturing methods that cut away material to create a part, 3D printing builds objects layer by layer. This technique offers unparalleled design flexibility, cost-efficiency, and sustainability, making it a game-changer in various fields.

How Does 3D Printing Work?

Digital Design: It all starts with a 3D model created using CAD (Computer-Aided Design) software. This model is then converted into a file format (like STL) that the printer can interpret.

Slicing: The design is sliced into hundreds or thousands of thin horizontal layers using slicing software.

Printing: The 3D printer then builds the object layer by layer using materials like plastic, metal, resin, or even biological materials.

Post-Processing: Once printing is complete, additional steps like polishing, painting, or curing may be applied to enhance the final product.

Applications of 3D Printing

3D printing is not confined to a single industry; its applications are as diverse as the materials it uses.

1. Healthcare

Prosthetics: Custom prosthetic limbs tailored to individual needs.

Bioprinting: Creating human tissue and organs for research or transplantation.

Surgical Models: Printing anatomical models to aid surgeons in planning complex operations.

2. Automotive and Aerospace

Manufacturing lightweight yet durable components.

Producing tools and jigs at a fraction of the cost.

Creating prototypes for faster product development.

3. Consumer Goods

Personalized products like jewelry, eyewear, and fashion accessories.

Rapid prototyping for innovation in design.

4. Education and Research

Teaching students about design, engineering, and innovation.

Enabling researchers to create precise models for testing and analysis.

5. Architecture and Construction

Designing intricate architectural models.

Printing entire structures, from houses to bridges, using specialized materials.

Advantages of 3D Printing

Cost-Effectiveness: Eliminates the need for expensive molds or tooling.

Customization: Enables production tailored to specific requirements.

Speed: Rapid prototyping significantly reduces product development time.

Sustainability: Reduces waste by using only the material needed for production.

Challenges in 3D Printing

While promising, 3D printing faces challenges:

Material Limitations: Not all materials are suitable for 3D printing.

Speed for Mass Production: Current technology can be slow for large-scale manufacturing.

Skill Requirement: Expertise is needed to design and optimize models.

The Future of 3D Printing

As technology evolves, so do the possibilities for 3D printing. With advancements in material science, speed, and machine learning, we are inching closer to a future where 3D printing becomes a staple in every household and business. Imagine printing your own tools, furniture, or even food at home!

Conclusion

3D printing is not just a trend; it’s a transformative force reshaping industries and inspiring innovation. Whether you’re a hobbyist exploring creative projects or a business leader seeking efficient production solutions, 3D printing offers endless opportunities. As the technology continues to mature, one thing is clear—the future is being built layer by layer.